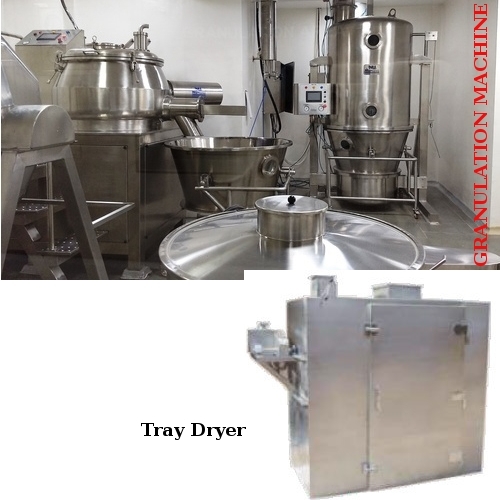

Granulation Machine and Tray Dryer

100000.00 INR/Unit

Product Details:

- Product Type Granulation Machine

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Color Silver

- Warranty 1 year

- Usage & Applications Industrial

- Click to view more

X

Granulation Machine and Tray Dryer Price

- 1 Unit

- 100000.00 INR/Unit

Granulation Machine and Tray Dryer Specification

- Electricity

- Painted

- 1 year

- Silver

- Industrial

- Granulation Machine

- Automatic

Granulation Machine and Tray Dryer Trade Information

- 1 Unit Per Day

- 1-8 Week

- All India

Product Description

The offered range of Granulation Machine and Tray Dryer has wide applications in pharmaceutical arena for their application specific structure. Designed by veteran technocrats, these machinery are acknowledged for their long working life, ease of maintenance and sturdy construction. The standard grade of these equipments has been verified on the basis of their structural strength, compatibility with different pharmaceutical substances, working life and production rate. The temperature level of these machines can be adjusted as per application needs. Energy efficient operation of these systems helps to reduce electricity bill. Easy to set up, these machines require less maintenance charge.

Granulation Machine and Tray Dryer can be used industrial sectors such as pharmaceutical, chemical processing, and food for quick granulation and drying of various types of materials. Let's explore each of these features in more detail:

Features of Granulation Machine and Tray Dryer

- Granulation and Tray Dryer machines are in high demand due to the following features:

- Rapid mixing results in an enhanced granulation process.

- The advanced granulation mechanism installed within this unit allows you to control the size of the produced products.

- It also comes with a coating function to coat granular products with a smooth coat.

- Easy to control blower system to efficiently circulate heated air with high uniformity.

- Advanced temperature control that provides quick drying as well as eliminates the risk of damage to the products.

FAQs: Granulation Machine and Tray Dryer

What are the advantages of using Granulation machine and Tray dryer?

Some of the common advantages of using Granulation machines and Tray dryers are:

- The combined granulation and drying action ensure quick processing as well as ensure easy installation within a small space.

- Reduced overall processing time which in turn led to improved productivity and low power consumption.

- The advanced granulation and drying processes give output with high quality while maintaining the size, density, and hardness of the products.

- The controlled temperature system makes the granulation machine and tray dryer suitable for heat-sensitive materials.

What types of materials can be processed using a granulation machine with tray dryer?

Granulation machines and Tray dryers can be used within various industrial sectors such as chemical, pharmaceutical, food processing, and many more. These heavy-duty machines are capable to process several products in various physical forms which include herbal extracts, food ingredients, chemical additives, pharmaceutical powders, chemicals, food ingredients, herbal extracts, and many more.

Safety considerations when using a granulation machine and tray dryer?

Granulation Machines and Tray Dryers are industrial systems that need to be run in controlled conditions. There are several considerations that need to keep in mind while using these machines:

- Always stick to the manufacturer's instructions and recommendations while the machines.

- Build a high-performance ventilation system within the area where the machine is installed to prevent the accumulation of volatile fumes or dust.

- For your own safety, it is always recommended to use personal protective equipment glasses, heads cover, gloves, and face masks when handling and operating the machine.

- Perform regular inspection and servicing of the machine to eliminate the risk of potential hazards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email