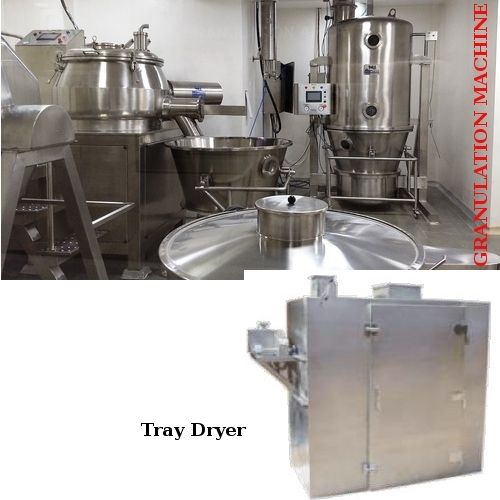

Pharmaceutical Fluid Bed Dryer

650000.00 INR/Unit

Product Details:

- Product Type Fluid Bed Dryer

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Galvanized

- Color Silver

- Warranty 1 year

- Usage & Applications Industrial

- Click to view more

X

Pharmaceutical Fluid Bed Dryer Price And Quantity

- 650000.00 INR/Unit

- 1 Unit

Pharmaceutical Fluid Bed Dryer Product Specifications

- Galvanized

- Electricity

- 1 year

- Fluid Bed Dryer

- Silver

- Industrial

- Automatic

Pharmaceutical Fluid Bed Dryer Trade Information

- 1 Unit Per Day

- 1-8 Week

- All India

Product Description

We are a prominent manufacturer, service provider and supplier of stainless steel Fluid Bed Dryer. This machine is required to dry pharmaceutical products by applying fluidization method. The manufacturing technique of our pharmaceutical machine is in sync with C GMP norms. The distinctive features of our durable Fluid Bed Dryer include its innovative design and advanced manufacturing technique, ability in uniform drying within a short span of time, noise and vibration free operating mode and pneumatic bag shaking mechanism. We also provide optional instruments for on lime sampling, solid monitor flow and PLC systems with this machine.

We are a well-known manufacturer and supplier of a high-performance Fluid Bed Dryer that is commonly used for drying pharmaceutical products using the hot fluidization method. It is in high demand among our clients due to its innovative and flawless design. The offered industrial-grade dryer helps to achieve uniform drying within a short time frame. The structural frame is fabricated by using top-quality alloyed steel that provides high strength and rigidity to withstand extremely high pressure and temperature. Pharmaceutical Fluid Bed Dryer is equipped with an air-flow controller that helps to control the flow rate of hot air entering the drying chamber. This machine is capable to process dry granules, powders, or other solid materials. The ventilation system of this unit eliminates the contact of fumes and materials to be dried to maintain their integrity.

Features of Pharmaceutical Fluidized Bed Dryer :

- Efficient and quick drying helps to prevent clumping or sticking of materials.

- It also comes with an exhaust system to efficiently remove moisture-laden air.

- The electrical heating system of this unit eliminates the risk of accidents due to fire as well as greatly reduces the risk of air pollution.

- The advanced filtration system of this unit helps to remove unwanted elements such as dust, particles, and other contaminants present in the incoming air.

Working Process of Pharmaceutical Fluid Bed Dryer:

- The drying process carried out within a Pharmaceutical Fluidized Bed Dryer goes through the following steps:

- Loading: Materials containing water or moisture such as wet granules, pellets, or powders are loaded into the drying chamber over the fluidized bed.

- Preheating: To eliminate the risk of thermal shock the heating chamber is preheated to low temperature which in turn protects the machine as well as helps to improve the quality of the dried product.

- Fluidization: After preheating the hot air enters the fluidized bed with the help of an intelligent air control system to uniformly distribute heat waves within the chamber.

- Product Movement: The mechanical agitation system of the pharmaceutical fluid bed helps to gently move the substances to ensure consistent and uniform drying throughout the bed.

- Cooling: After completion of the drying process the product is cooled to safely extract them from the drying chamber.

FAQs : Pharmaceutical Fluidized Bed Dryer

What is a pharmaceutical fluid bed dryer?

Pharmaceutical Fluid Bed Dryer is a specialized machine that is commonly used in industries dealing in the manufacturing of medicinal products such tablets, capsules, topical gels, and many more. This machine is used for the processing of raw materials to make them free from moisture and water content. It is in high demand due to its high operational speed with zero risk of damages to the produced under the processing phase. It is designed to automate the pretreatment process as well as improve the quality of materials.

What are the advantages of using a pharmaceutical fluid bed dryer?

The advantages of Pharmaceutical Fluid Bed are listed below:

Rapid drying with high uniformity.

Improved quality of dried products.

Efficient heat transfer and less power consumption.

Capability to handle granular, powdered, and small solids.

Scalability, which makes it suitable for small to large-scale industrial as well as laboratory applications.

Rapid drying with high uniformity.

Improved quality of dried products.

Efficient heat transfer and less power consumption.

Capability to handle granular, powdered, and small solids.

Scalability, which makes it suitable for small to large-scale industrial as well as laboratory applications.

Are there any considerations for using a pharmaceutical fluidized bed dryer ?

Some of the important points while using a pharmaceutical fluid bed dryer are:

- Size of the particles that are going to be dried. If the size is too small then it may require equipment and measures to efficiently perform drying.

- The content of moisture and water present within the raw materials is also an important factor as it helps to determine appropriate drying parameters.

- Heat sensitivity of products, there are some products that may get damaged within high-temperature conditions; hence it is advisable to heat these materials at low temperatures.

- It is important to keep in mind to determine if the product is hazardous or not, as the toxic materials may release irritating fumes that may cause damage to the operator's health.

Which Types of materials that can be dried using a pharmaceutical fluidized bed dryer?

There is a wide variety of products that can be easily processed within the pharmaceutical fluid bed dryer. Some of them are mentioned below:

- Powders: Substances such as excipients, active drugs, and powdered formulations can be dried in a pharmaceutical FB dryer.

- Granules: Products from wet granulation processes are available in different-sized granular forms that can be easily distributed over a fluid bed to make them moisture free.

- Agglomerates: These substances can also be dried in FB dryers to eliminate the risk of caking.

- Coated particles: As the Fluid bed dryer uses dry air for moisture or water removal, the products with film coatings or sugar coatings can be dried within this heavy-duty dryer unit.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email